By definition, cloth is a pliable material made by felting, weaving or knitting that is used for clothing, drapery, bags, etc. As felting, weaving, and knitting are unrelated handcrafts, their histories will be treated separately.

FELT

Felt is perhaps the oldest method of making cloth, because it’s the simplest – requiring the fewest tools. Unfortunately, the earliest surviving traces of felt date back only 8500 years, though we suspect the practice was developed much earlier. Felt can only be made using wool or some similar animal fibre – plant or man-made fibres don’t naturally stick to each other.

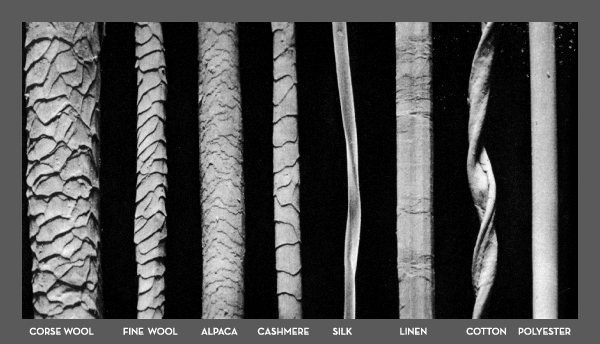

Electron Microscope photos of fibres.

To quote Wikipedia on the felt making technique known as wet felt (shown below). “These types of fiber are covered in tiny scales, similar to the scales found on a strand of human hair. Heat, motion, and moisture of the fleece causes the scales to open, while agitating them causes them to latch onto each other, creating felt. There is an alternative theory that the fibers wind around each other during felting. Plant fibers and synthetic fibers will not wet felt.”

WEAVING

Weaving is the art of interlacing thin cords at right angles to make larger shapes. One can weave leather strips to make belts, and plant materials to make baskets, and perhaps these are the earliest examples of weaving. The earliest baskets yet discovered have been carbon-dated to 10,000-12,000 years ago. But plant materials degenerate quickly; much faster than bone. “Modern” human bones have been carbon dated to 250,000 years ago. Who knows when the first basket was woven?

To make cloth, however, one can’t weave unless one has thread, and thread as we know it took a long time for humans to develop. One of humankind’s earliest, most important, and most brilliant inventions was string. We had been using roots, vines, stalks, and strips of bark for millennia as early types of rope, nets, and string. But all were limited by their original length and strength. Someone discovered that twisting shorter pieces together at staggered intervals could produce longer, stronger lengths, but how to keep them from unravelling?

Plant fibres are the “backbones” of plants. They’re the tough material, like the tubes that make wood fibre, that allows a tall plant to stay stiffly upright. Some plants are more fibrous than others, and some plant fibres stay tougher longer after the plant dies than others. Early humans noticed these differences and soon began selecting plants whose fibres were longest, most durable, and were most easily separated from the rest of the plant. In Southern Europe and the Middle East the favoured plants were hemp and flax.

In the Caucasus Mountains of Georgia, pieces of twisted, dyed flax were found in a cave. They’re at least 30,000 years old. Their discoverer, Harvard archaeologist Ofer Bar-Yosef, doesn’t believe the fibres were woven into cloth, but were were probably braided together, macrame style.

It took thousands of years of experimenting with ways to twist fibres to discover the secret of string. When a single plant fibre is twisted, it tends to spring back to its original shape. But if two or (better) three fibres are twisted in one direction while simultaneously being wrapped around other 2-3 fibre strands in the opposite direction, their combined spring-backs work against each other, locking them into place.

By gradually adding more fibres, a few at a time, string can be made to an infinite length. Rope was probably the first product of this technique, and indeed, a piece of heavy cord, twisted from multiple smaller twisted cords, carbon dated at 15,000 years old, has been found in the caves of Lascaux, France.

Netting would have been another early product of string, and with it a greatly expanded ability to catch fish and animals. Carrying bags would revolutionize transport. String made life easier in so many ways.

Gradually, string became finer while retaining strength, until bits of thread and cloth begin showing up in archaeological sites in the Near East, dated to around 9000 years ago. How was this cloth made? First let’s look into how they made (and still make!) thread. The YouTube below shows a drop spindle spinning wool yarn, but the process is much the same for flax. A drop spindle can make thread 4 times faster than thigh-rolling; still, it takes a LOT of thread to make a piece of fabric – in terms of a weavers’ time, about 8 – 10 times longer to spin the thread than to weave that thread into cloth.

Until about 10,000 years ago, most of the people on the planet made a living either as hunter-gatherers, or as animal-herding nomads; both requiring their family or tribe to be nearly constantly on the move. So tools were simple – the less to carry the better – especially as we hadn’t yet invented the wheel. The earliest weaving involved almost no tools at all. It was basically an elaborate form of braiding, now called finger weaving.

It’s easy to see that the wider and longer the band you want to weave, the more difficult finger weaving becomes. You were weaving from the top down, and the longer the threads, the easier they became entangled. So the next innovations in weaving involved, 1. tying the lengthwise threads (called warp) on spreader sticks at both ends, and perhaps a couple more spreader sticks midway to keep spacing even, 2. fastening one end to something solid, and the other end around your waist, 3. leaning back to make the warp tight, 4. tying a single long cross thread (called weft) to a stick to make it easier to push between warp rows, (black stick in this video), 5. tying every other warp string to a single long stick (called the headle), so all the tied threads may be lifted at once (red thread in this video), 6. using a wide flat stick to provide more space to push the weft stick between rows, then to tamp the weft thread tight against your body. Now you’re weaving from the bottom up, on what is commonly known as a Backstrap Loom.

The Backstrap Loom is ideally suited to a nomadic lifestyle – few components to transport, easy to set up. However, even the Backstrap Loom has limits to the width of cloth comfortably woven. Also, the wider the cloth, the harder it is to make the sides even and straight.

In the dry, southern Middle east, where rain was not an issue, a Horizontal Loom was developed, where the width is limited only by the length of sticks used to tie the warp. The sticks are held firm by stakes pounded in the ground, thus freeing the weaver to attend to other tasks (like cooking & raising children) as needed.

The Horizontal Loom has been the primary type of loom used in the drier parts of Middle East, from ancient Egyptian times until the present. Notice in the YouTube below how at around the 5:20 mark, large fabric is made by passing the warp (and later weft) from one person to another.

But what about wetter more northern places, where weaving can’t be left out in the weather? Fortunately, humankind about this time (10,000 – 7,000 B.C.) made a dramatic discovery that forever changed the way we live.

In central Anatolia (now Turkey) and parts of Syria and Iraq, climate changes favoured the growth of grasses, and they grew in such abundance that people had more seeds than they could eat, or even store over winter. With a secure food supply, people could stop moving around all the time, could build permanent dwellings, live in fortified clusters for self-defence, nurture craftsmen who had the time to develop skills in carpentry, pottery, trade, metalworking, and weaving. In these newly “permanent” dwellings, space was at a premium, so a Vertical Loom was developed.

At first, the Vertical Loom looks like a Horizontal Loom tipped up on its side. There are two crucial differences, however. First, the warp is not tied at both ends – the bottom of the warp is held taught by weights, giving this loom the alternate name of Warp-Weighted Loom. Also, the weaving is done from the Top Down. In other words, the weft is pounded tight with an upward motion. The weaver is always standing (saving space), and the weaving is always at eye level (saving backs).

As is explained in the following YouTube, this vertical Warp-Weighted Loom was the preferred loom technology in Europe until about 1000 AD, due to the cramped cottages and lack of interest in innovation of ancient and medieval times.

Many looms dispensed with the a-frame stand shown in these videos, relying instead on side posts sunk in holes in the earthen floor, or simply leaning the loom against a wall, saving even more space and requiring less wood.

KNITTING

Knitting is the last of the cloth-making arts to develop. What little we know is explained here http://sheepandstitch.com/the-history-of-knitting-part-1-mysterious-origins/